The second of a 4-part series chronicling the last 6 months of restoration of the Fife Cutter Moonbeam IV in Burma back in 2002. (View the first part of the series here)

Arriving for a restoration 80% of the way through has its disadvantages but the best part is that, from my point of view, you get stuck into the most interesting work. The tiresome process of repairing and replacing the rusty frames, executed so that each frame’s shape and position was respected, designing and building a jig to drop off the 28 ton keel, lighten it to the original 25 tons and fill the voids, are all work that’s essential to accomplish an accurate restoration – and this had all been completed over a year before and approved by Lloyds.

During this time a team of 15 core carpenters had been built up and they had already spent months inspecting, repairing and re-fastening the teak planks leaving more than 80% original from 1914. 8-9000 silicone bronze fastenings were used and all other holes plugged accordingly. Caulking was loosely applied to make sure the planks had room to expand and then covered with red lead putty. It had been decided to go with the traditional hull covering under the waterline and so tar was slapped on, followed by Irish felt, and eventually copper sheathing fastened by thousands of copper tacks.

The interior was also halfway there. Most of the systems were in place and the woodwork was ongoing. Beautiful solid panelling of padauk (Burmese rosewood) on frames of yinmar (Burmese satinwood) with teak sole boards and a stairwell and taffrail that came from a single trunk of old teak. In general Moonbeam looked great, but there was still a lot to do!

With these 15 carpenters and an additional 5-10 ‘crew’, Morgan ran the team commanding respect and certainly with a hint of colonial authority. Even with the language barrier the point was made, often via our ‘translator’, and while we had to watch everything closely the team pulled together and eventually delivered. There were of course upsets. We had to make new pin rails, positioned at the bulwarks either side of the mast, and we wanted to use two of the old keel bolts for the material. A lovely feature that would tell a story let’s say! So sketches were drawn up and were explained to the nodding, betel leaf-chewing, ‘lathe man’. He got to work. Whether it was lost in translation, or the carcinogenics of the betel leaf were too much to handle, the holes for the pins had been made too wide and the pins slipped right through! No belaying any line to this pin rail then and YES, there was a slight tirade but you can be assured the same mistake wasn’t made twice!

A majority of the crew chewed betel leaves but it didn’t seem to affect their work. (After much fuss I tried it on one occasion and it was quite the hit!) Their teeth were somewhat deteriorated with smiles of red gunk but this is how they rolled and they just got on with it. Names were hard to get a jist of so nicknames were made up: ‘Lathe man’, ‘Blocky’(in charge of making the blocks), ‘Dumbo’ (metal worker with big ears), ‘Singer’ (made cushion covers) and ‘Blacky’ (the very popular adopted mascot – a dog) to name a few. Menzo, the general help did a little of everything from being the Chef’s assistant to general tidying up and he always came with a happy face and a cheroot (a type of cigar particularly popular in Burma) hanging from his lips.

Morgan had placed me in charge of the towering rig, its fittings and the deck layout, which was a challenge and responsibility that I embraced and enjoyed. After the team had gone home we would retire to our crew house 50 metres down the road within the compound, where a subdued Burmese lady would cook western food for supper (which resulted in some interesting results) and then return to the peace and quiet on board to run cables in the bilge and fight off massive mosquitoes. With Morgan pushing to leave and always claiming, from the beginning of my 6 months in Burma, that “we have to work long hours now as we are leaving next month”, it was a busy time. Sunday was the only day I had off and I would run off to the seclusion of a tropical city hotel, walk in as if I owned the place and lounge beside the pool!

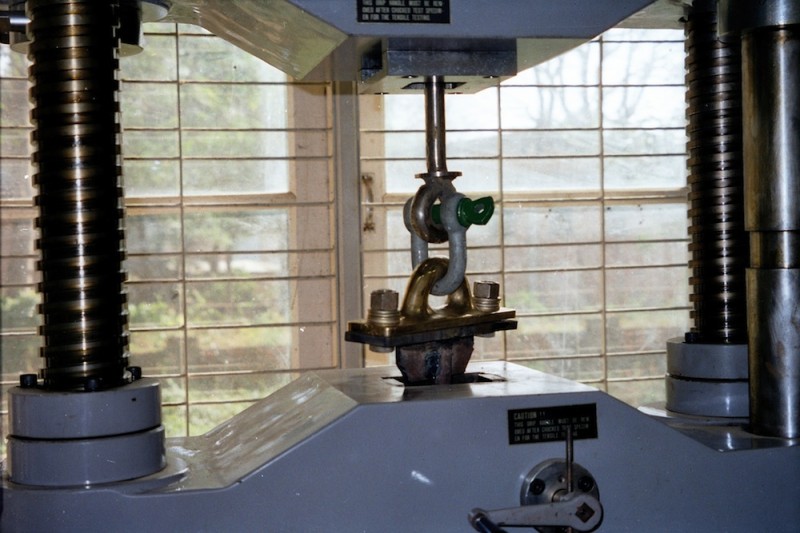

As a picture captures a thousand words below you can see images of the work undergoing during this time. Painting, French polishing, spar and block construction, strength testing deck fittings, lathe work and more.

After 3 months in the water, sufficient time for the planks to expand and settle, the bilge pump was still running to excess. The original idea to caulk lightly had not worked and as a result Moonbeam was hauled out and checked over by T Nielson and Co. – traditional shipbuilders and riggers from the Gloucester Docks. The planks had not expanded as much as expected and had in-fact reabsorbed the water and hardly moved at all. With Moonbeam out of the water the ‘mission’ developed. The next weeks involved stripping off and numbering all of the copper sheets, removing the Irish felt and the worst job, scrapping off the tar. If you have ever worked with tar before, you will know that it gets absolutely everywhere and doesn’t come off. Think of Sikaflex but 10 times worse! This was all carried out on precariously erected bamboo scaffolding.

After she had been totally stripped down she was re-caulked with heavy duty oakum and the seams were relined with red lead putty. As each copper sheet had been fixed with copper tacks each and every one of these 30,000 odd holes had to be re-plugged. I counted about 50 workers bundled together re-plugging the holes over two days, all balancing ominously on the bamboo scaffold. Only in Burma! Tar followed, boiled in a drum next to the boat on top of burning bamboo and supervised by bare-footed crew. The Irish felt was then replaced followed by the copper sheets, all of which had been de-tempered by Dumbo and his blow torch.

Fingers were crossed when she was re-launched. Thankfully the leaking had well and truly stopped.

More to come in Part 3 of the Myanmar Mission. Stepping the rigs, completing the remaining tasks and a little more about Burma under military rule!